Finding Signals in Noise: How AI Clustering Can Unlock Methane Insights

The oil and gas sector is under pressure to reduce methane emissions and find ways to improve operational efficency. Regulators are moving toward measurement-informed reporting, investors are seeking transparency, and operators are grappling with the operational complexity of turning raw data into actionable insights.

A key untapped opportunity lies in Supervisory Control And Data Acquisition (SCADA) data. Across thousands of sites, operators collect terabytes of high-frequency time-series signals from compressors, tanks, and flare systems — yet most of this information sits underutilized. While SCADA was designed to support safe operations, it also contains hidden fingerprints of emissions events.

Making sense of this data is not trivial. Signals vary widely across facilities and companies, sensors drop out, and naming conventions differ from one site to the next. Detecting emissions reliably in this noisy environment requires a new class of tools.

Clustering Emission Events with AI

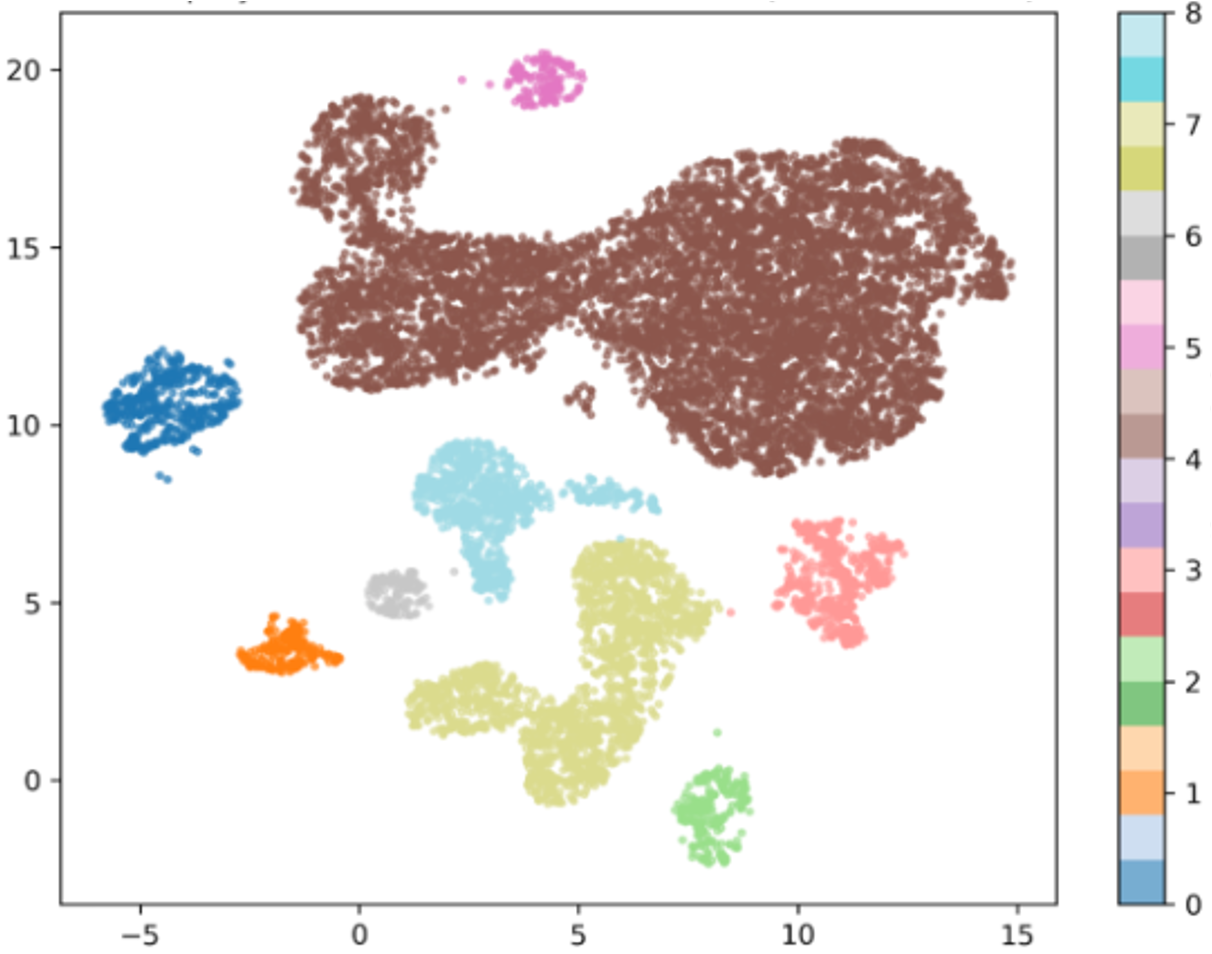

One promising approach is clustering analysis — grouping emissions events that look similar across multiple sensors and operating conditions. By using clustering algorithms, our analysts can identify patterns, spot outliers, and accelerate the process of labeling events for AI training.

Our data science team, led by Jashan Khehra, recently demonstrated this by creating a powerful clustering algorithm well-suited to noisy, high-dimensional data. With support from Dan Steeves (Senior Emission Analyst and SCADA specialist), the team started from dozens of SCADA dimensions, standardizing each sensor so they all carried equal weight. The data was then reduced to fewer dimensions for visualization. Next, they transformed the data into a space where emissions events could be meaningfully compared.

The result? Clear clusters of flaring events began to emerge. In one graph, distinct event families appeared, each representing a different operational signature. In another, rare outliers stood out like beacons — the very anomalies that might otherwise slip through unnoticed.

By labeling these clusters, we begin to learn the causation of the event, by linking anomalies across multiple signals through our models. Imagine being able to not only confirm that flaring occurred, but also trace it back to the exact compressor or tank behavior that triggered it.

Why This Matters

This kind of approach has major implications for the industry:

- Faster Event Detection: Reduce time spent manually combing through SCADA logs.

- Root Cause Analysis: Link cross-signal correlations to identify why emissions occurred.

- Predictive Capability: Move from reactive detection to forecasting events before they escalate.

- Scalable Insights: Apply the same framework across multiple facilities, even when SCADA configurations differ.Operational Efficiency: Increase

- Operational efficiency through the lens of strategic emissions management.

It also lowers the barrier to adoption. No additional hardware is needed — just smarter use of the data operators already collect.

The Road Ahead

As AI models improve, SCADA data can transform from a compliance burden into a predictive intelligence tool. For operators, this means not just reducing emissions — but doing so more efficiently, with less operational overhead.

At Arolytics, we are forging the path for how AI can help unlock this future. The work shared here was led by Jashan Khehra, one of our in-house Data Scientists, with domain expertise from Dan Steeves, a Senior Emission Analyst and SCADA specialist. Their collaboration highlights the importance of pairing technical innovation with deep operational knowledge.

“Bringing diverse SCADA signals together into meaningful clusters is the path forward for solving this challenge. It’s how we turn raw, fragmented data into actionable intelligence — and ultimately into real emissions reductions.”

— Stephan Becker, Chief Product & Technology Officer, Arolytics

This is just one example of how new approaches to SCADA data can reshape methane management. As the industry continues to push toward ambitious reduction targets, these kinds of innovations will be essential to meeting them

Stay tuned for an exciting product announcement coming in October!

Let us explore which applications are suitable based on your specific situation. Contact us to learn more, and discuss pilot opportunities that are custom to your unique emission source challenges and available data: info@arolytics.com.